Proesa Protexa

Mexican leaders providing high-tech coating application to auto parts and electronic devices

Mexican leaders providing high-tech coating application to auto parts and electronic devices

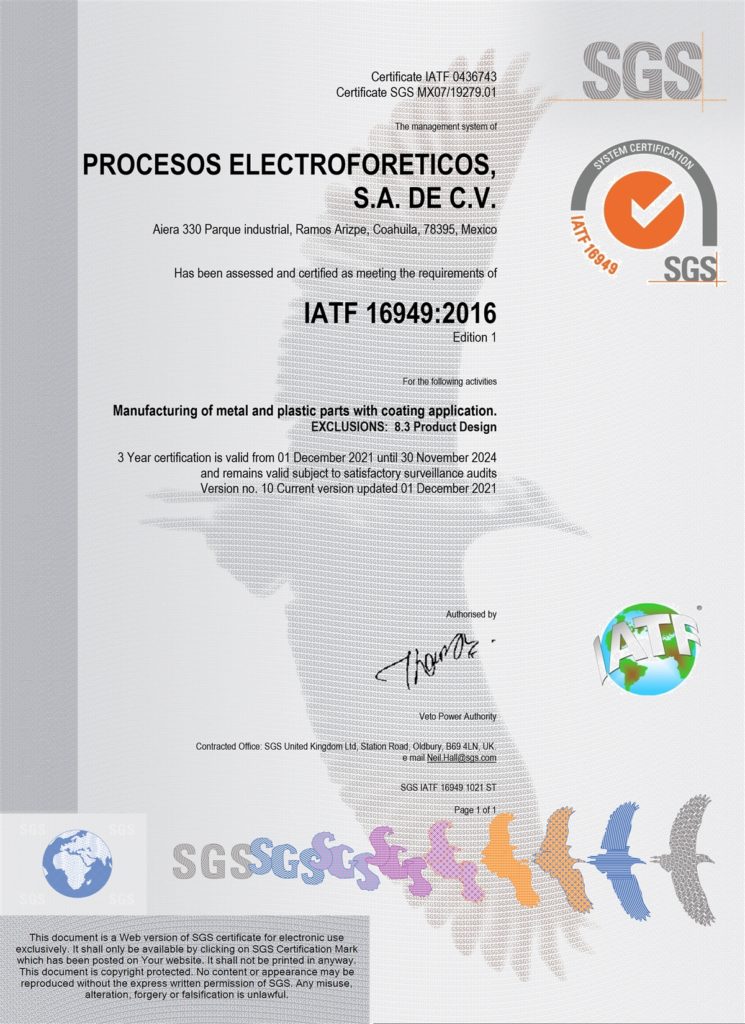

We provide high-tech anticorrosive coatings to metal and plastic parts of automotive, electronics and industrial sectors, through two processes: e-coat and powder painting.

Our two plants, located in Ramos Arizpe, Coahuila and the city of San Luis Potosí, are the largest of its kind by capacity installed by a national firm in Mexico.

E-coat

electrophoresis

Powder coating